Anodizing vs. Painting: Why Anodizing is Superior Finish for Aluminum Beads in Interior Design

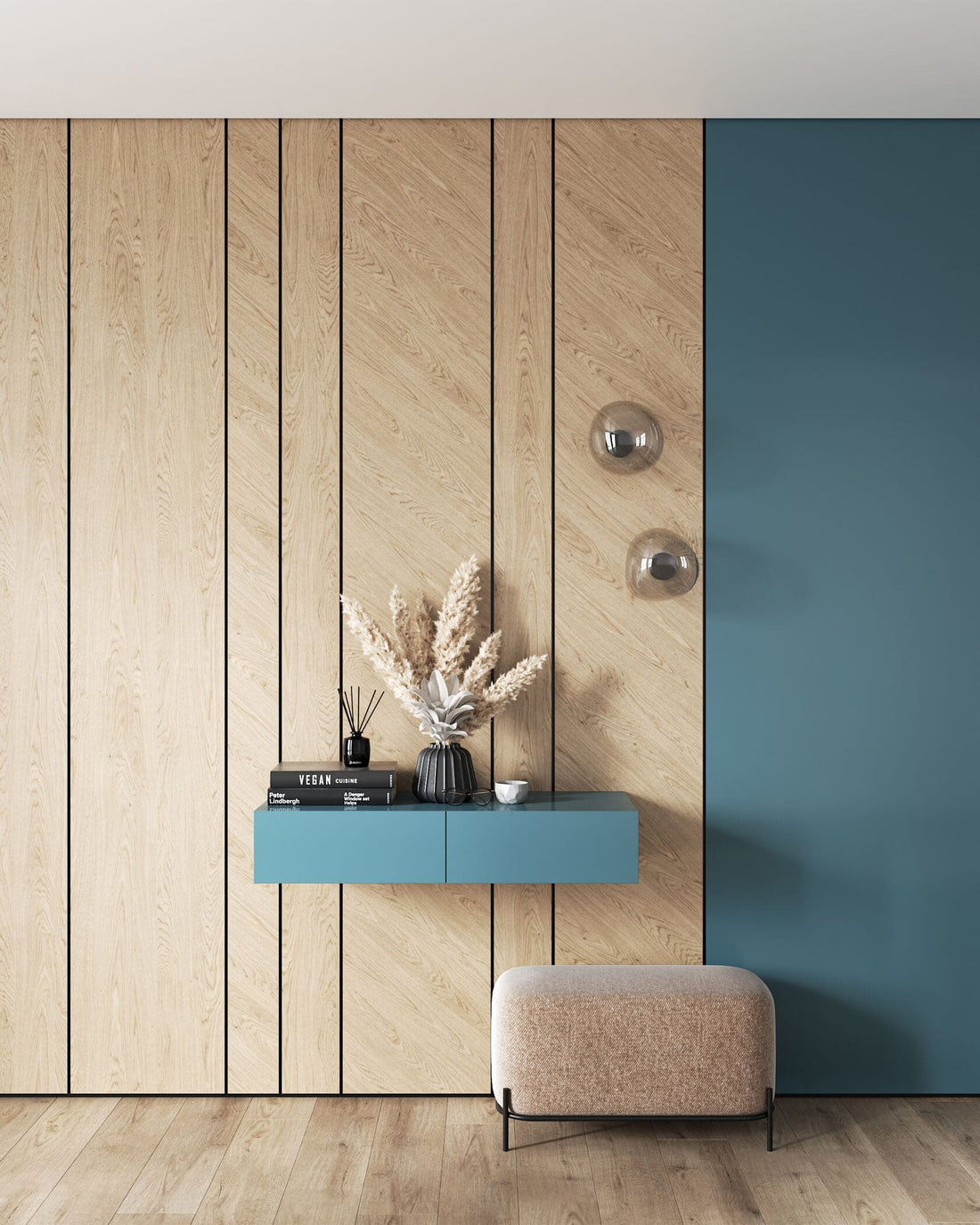

Aluminum trims have become essential in modern interior design due to their flexibility and sleek appearance. Commonly used in shadow gaps, skirting boards, and lighting solutions, they enhance minimalist and high-tech aesthetics. These trims need to fulfill functional requirements while maintaining a refined finish over time. Anodizing, particularly with Aluminus aluminum trims, provides clear advantages over painting, offering aesthetic and practical benefits that meet the rigorous standards of interior design professionals.

What is Anodizing?

Anodizing is an electrochemical process that alters the surface of aluminum, creating a durable, corrosion-resistant oxide layer. Unlike paint, which merely coats the surface, anodizing modifies the material itself, forming a protective layer that becomes integral to the aluminum. This is done by immersing aluminum in an acid electrolyte bath and passing an electric current through it. The result is a surface finish that outperforms painted alternatives in both bonding strength and durability. While paint can chip or peel, anodized trims offer a surface that is much harder and longer-lasting.

Durability and Longevity

Anodizing provides superior durability compared to painting. Aluminum trims treated with anodization are highly resistant to wear, corrosion, and UV exposure, making them ideal for long-lasting interior applications. Environmental factors, like moisture or chemicals, can degrade painted surfaces quickly. However, anodized finishes, such as Aluminus, resist these elements and do not chip, peel, or fade, ensuring a reliable and long-term solution, especially in high-traffic or prominent areas.

Aesthetic Advantages

Anodized aluminum trims offer a metallic sheen that complements modern design. Unlike paint, which can appear flat, anodized surfaces provide a consistent, elegant finish that pairs well with wood, glass, or stone. Moreover, anodizing allows for a variety of colors while maintaining the metallic quality of aluminum, giving designers flexibility to match finishes with the overall design scheme. Whether it’s natural silver or darker tones, Aluminus anodized trims enhance the aesthetic appeal of any interior space.

Maintenance and Cleaning

Anodized aluminum trims are also easier to maintain than painted ones. They resist stains and scratches more effectively, maintaining a polished look with minimal effort. This makes anodized finishes ideal for areas exposed to dirt or contaminants. A simple wipe-down restores the anodized trim’s luster, reducing both maintenance time and costs. The low-maintenance properties of anodized aluminum make them a highly practical choice for interior design applications.

Sustainability and Eco-Friendliness

Anodizing is a more sustainable option than painting. The process generates minimal waste and uses fewer harmful chemicals. Anodized aluminum is 100% recyclable, making it a responsible choice for eco-conscious designers and builders. Unlike painting, which may involve volatile organic compounds (VOCs), anodizing is a safer, more environmentally friendly process. This aligns well with modern green building practices, especially for trims produced by companies like Aluminus.

Cost Efficiency Over Time

While anodizing may initially cost more than painting, its long-term benefits make it the more cost-effective solution. Anodized trims require significantly less maintenance, and their enhanced durability means fewer repairs or replacements. Over the lifespan of the product, the overall cost of anodizing trims is lower compared to painted alternatives.

Applications in Interior Design

Anodized aluminum trims are highly versatile and used in various interior design applications. From functional elements like skirting boards to decorative features that enhance overall design, architects and designers frequently turn to anodized trims for high-end, modern looks. The trims are also integral to lighting systems, particularly with LED lighting, adding both functional and visual impact. Aluminus anodized trims are especially favored for projects requiring sleek, minimalist designs.

Conclusion

Anodizing clearly offers advantages over painting when it comes to finishing aluminum trims in interior design. The durability, resistance to wear, aesthetic flexibility, ease of maintenance, and sustainability make anodized finishes the preferred choice. Aluminus anodized trims provide long-lasting, high-quality solutions for architects and interior designers. Choosing anodized trims ensures that design elements not only meet but exceed expectations, standing the test of time in both residential and commercial interiors.